-

Finished Products

-

Product Parameters

Model:FQJ-3

Maximum width of unwinding 1000/1600/2400mm(Or customized according to customer requirements)

Maximum diameter of unwinding Φ1100mm

Unwinding deviation error ≤±0.05mm

Minimum slitting width 30mm

Slitting speed 0-150m/min (Constant speed control)

Slitting thickness 15g-800g

Slitting accuracy ≤±0.05mm

Maximum diameter of winding Φ600mm

Inner diameter of winding and unwinding paper core Φ75-80mm(Or customized according to customer requirements)

Diameter of winding and unwinding shaft Φ74mm(Or customized according to customer requirements)

Total power 5.5KW

Power supply 380V/50HZ

Total weight of the machine 1000KG

Overall dimensions (length * width * height) 1900-2200-1500mm

-

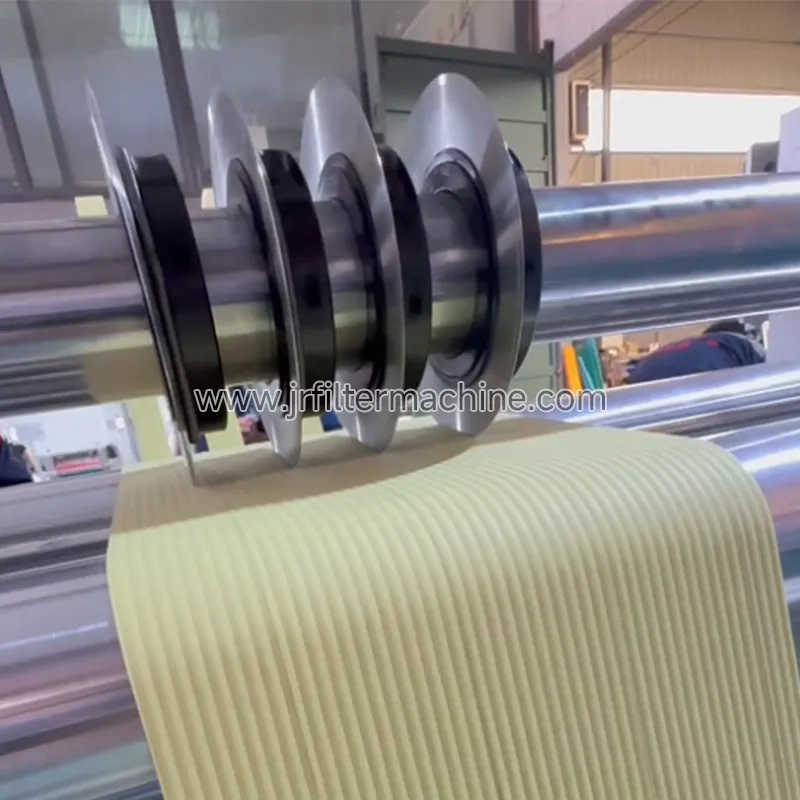

Product Features

High-precision slitting: It can achieve millimeter-level or even higher precision slitting, ensuring the uniform width of the filter paper after slitting, meeting the strict size requirements of PU car air filter production.

High-speed operation: It has a higher slitting speed and can be adjusted according to production needs. Under the premise of ensuring slitting quality, it improves production efficiency and meets the needs of large-scale production.

Good stability: The structural design and control system of the equipment ensure its stability during long-term operation, reduce production interruptions caused by equipment failure, and reduce maintenance costs.

Strong adaptability: It can adapt to the slitting of filter papers of different materials, thicknesses and widths. Through simple parameter adjustment and tool replacement, it can meet the production needs of various specifications of PU passenger car air filter papers.

-

Application

The production line is applied to auto tri-filter industry, hydraulic pressure, purification and water treatment industries, etc.

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.