-

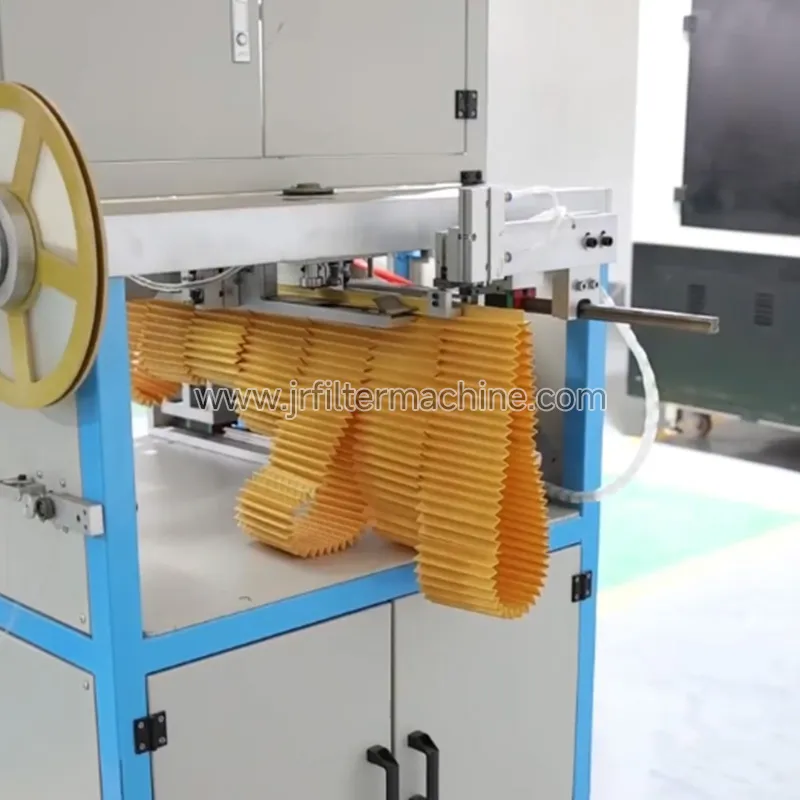

Finished Products

-

Product Parameters

Model:JR-CSJK

Working range: welding paper with a folding height of more than 10mm

and a length of less than 250mm

1 person operates production

7-inch touch screen,Xinjie PLC

Production capacity: 500pcs/h

Dimension: 1300*1400*1600mm

Weight: 300kg

Power: 3KW

-

Product Features

High efficiency and energy saving: Using the principle of high-frequency vibration friction to generate heat, welding and edge joining can be completed in an instant. At the same time, its high energy conversion efficiency and non-contact heating reduce energy loss, which can effectively reduce energy consumption costs and conform to the production concept of environmental protection and energy conservation.

High and stable welding quality: During the welding process, ultrasonic energy is concentrated and acts on the welding area, causing the material molecules to vibrate and fuse rapidly. The resulting weld joint has high strength and good sealing, and is not prone to problems such as debonding and cracking.

Easy to operate and highly automated: The equipment is equipped with a PLC control system and a touch screen human-machine interface, which can display welding parameters (amplitude, pressure, welding time) in real time. It supports the storage and call of more than 100 sets of process parameters to meet the needs of rapid production changes for filter materials of different specifications.

Low maintenance cost: Ultrasonic welding technology is mature and reliable, with a low equipment failure rate. It can effectively reduce production downtime caused by equipment failure and improve equipment utilization and production continuity.

-

Application

The production line is applied to auto tri-filter industry, hydraulic pressure, purification and water treatment industries, etc.

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.