-

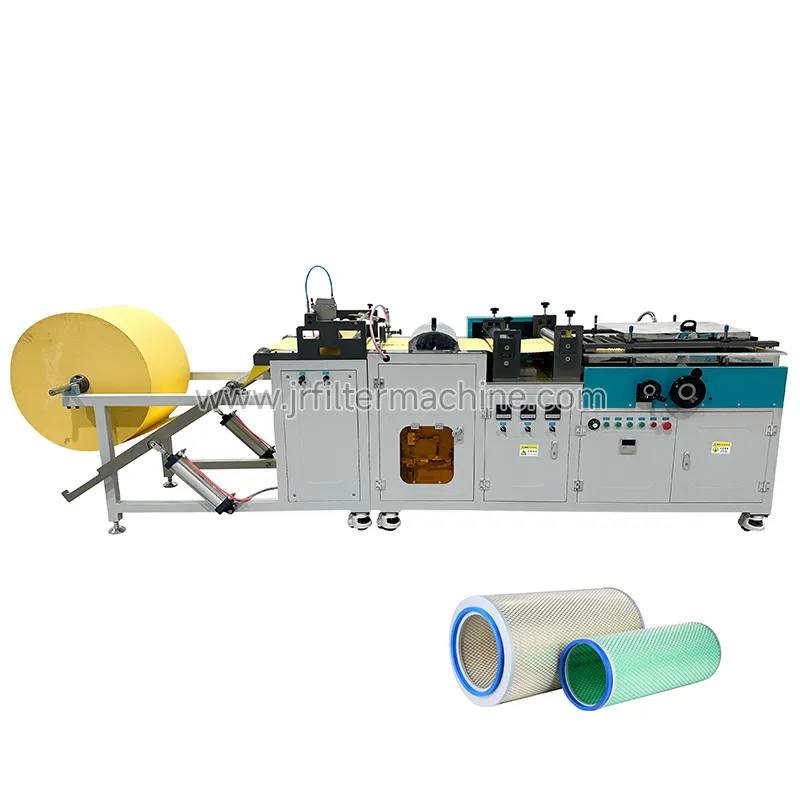

Finished Products

-

Product Parameters

Model:NX-5-600

Working speed: 15-30m/min

Paper width: 100-590mm

Folding height: 7-28mm

Roller specifications: can be customized

Temperature control: 0-190℃

Total power: 8KW

Air pressure: 0.6MPa

Power supply: 380V/50HZ

Equipment weight: 1000KG

Dimensions: 1630*960*1350mm

2130*1010*1350mm

-

Product Features

High-precision folding: It can achieve precise folding size and shape control to ensure the folding accuracy and consistency of the air filter core. This is crucial to improving the filtration efficiency and service life of the air filter.

High production efficiency: It adopts automated operation mode, fast folding speed, and can meet the needs of large-scale production. Compared with the traditional manual folding method, the production efficiency can be increased several times or even dozens of times.

Strong flexibility: It can adapt to the production of air filter cores of different specifications and shapes by replacing molds or adjusting parameters, and has strong versatility and flexibility.

Good stability: The equipment has a reasonable structural design, uses high-quality components and advanced manufacturing technology, and has high stability and reliability. During long-term operation, it can maintain a good working condition and reduce the probability of failure.

Easy to operate and maintain: With a user-friendly operation interface, operators can easily set equipment parameters and control equipment operation through the touch screen or buttons. At the same time, the equipment is also easy to maintain and easy to perform daily inspections and repairs.

-

Application

The production line is applied to auto tri-filter industry, hydraulic pressure, purification and water treatment industries, etc.

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.