-

Finished Products

-

Product Parameters

Model:YFCR-1

Machinable range: paper width 400mm, 52(Inside diameter)-300(Outside diameter)mm

paper width 550mm, 52(Inside diameter)-400(Outside diameter)mm

paper width 800mm, 75(Inside diameter)-400(Outside diameter)mm

paper width 1000mm, 100(Inside diameter)-450(Outside diameter)mm

Width of material: Max 400/550/800/1000mm

Material diameter: Max 800mm

Design speed:15-40m/min

Power supply: three-phase, 380V/50HZ

Power:6KW

Dimensions: 1900*1200*1900mm(808KGS) 1950*850*1950mm(198.5KGS)

-

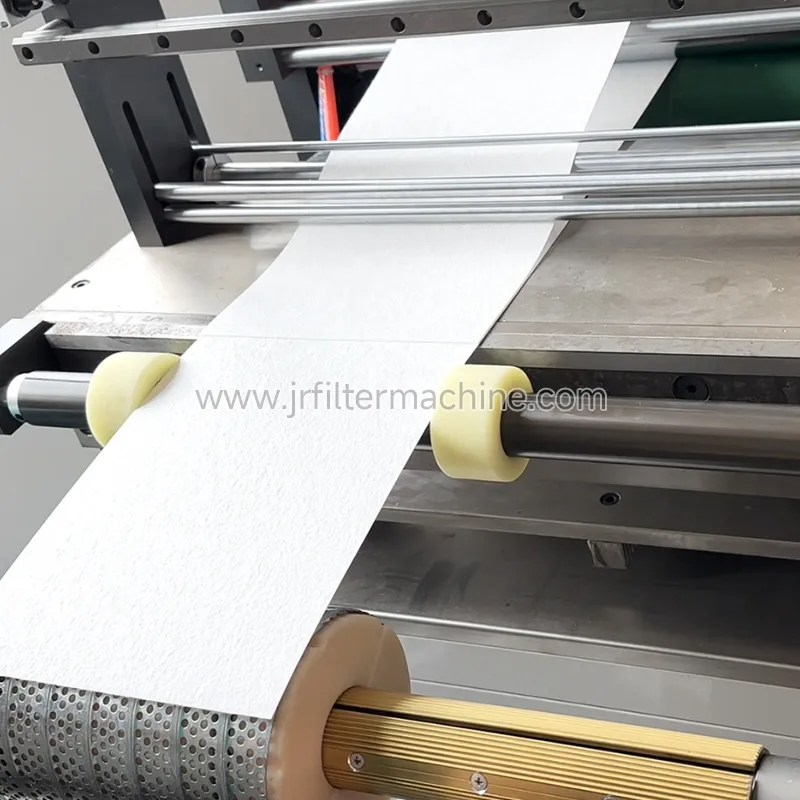

Product Features

1.The control system adopts PLC or DCS integrated control, supports manual/automatic switching, can accurately adjust key parameters such as feed speed, separation pressure, winding tension, etc., and has fault alarm, data recording and remote monitoring functions, which makes it easy for operators to understand the equipment operation status in real time and ensure the continuous and stable operation of the entire oil and gas separation line.

2.The parts of the equipment that come into contact with the oil separator and the separation paper are mostly made of corrosion-resistant and wear-resistant materials (such as stainless steel or special alloys) to extend the service life and reduce maintenance costs, adapting to the special requirements of the oil and gas processing environment.

3.High-efficiency adsorption: The roll paper is made of high-density fiber materials (such as wood cellulose and synthetic fibers), which have a large specific surface area and good lipophilicity. It can efficiently intercept tiny oil droplets and the separation efficiency can reach more than 99.9%.

-

Application

The production line is applied to auto tri-filter industry, hydraulic pressure, purification and water treatment industries, etc.

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.